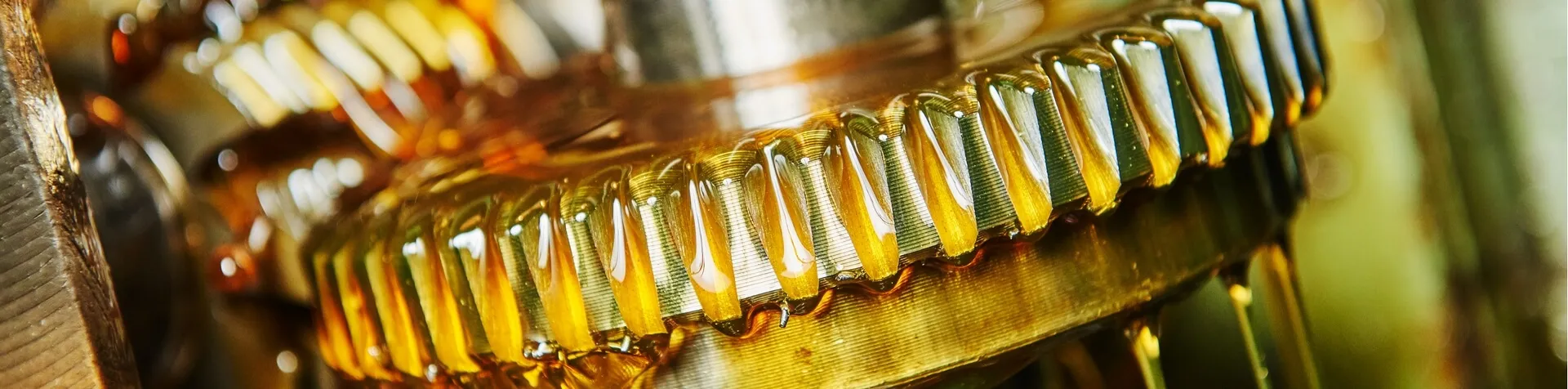

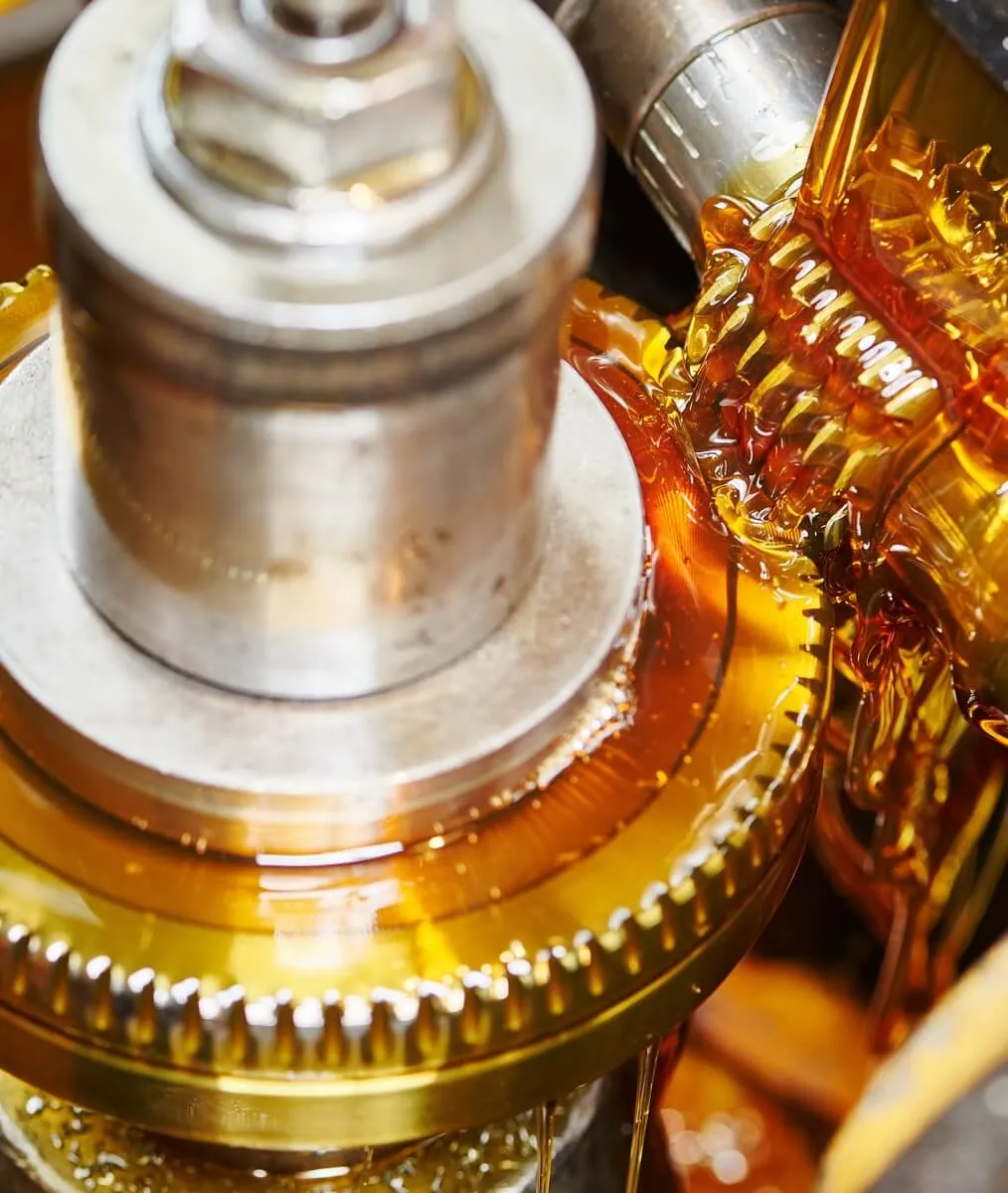

Anti-Wear & Extreme-Pressure Additives

In demanding mechanical environments, the breakdown of the lubricant film can lead to direct contact between metal surfaces, causing wear, heat build-up and premature component failure. To prevent these issues, Lumar offers a complete range of anti-wear and extreme-pressure (EP) additives designed to enhance equipment protection.

Description

Anti-wear additives act by forming a protective film on metal surfaces, either through physical adsorption or chemical reaction, to limit micro-welding during intermittent contact under mixed lubrication conditions. They are particularly effective in systems where viscosity alone is no longer sufficient to ensure full separation of surfaces.

Under extreme load conditions, the action of EP additives consists of chemically reacting with metal surfaces to prevent local welding that can cause irreversible damage, especially in heavy-duty gears, compressors or high-load transmissions.

With a wide variety of active technologies (organic, sulfur-based, phosphorus-based and more), Lumar offers high-performance solutions tailored to each operating environment, ensuring reliability, sustainability and safety for the most heavily stressed mechanical systems.

Among anti-wear and extreme-pressure additives, we offer:

- Amine phosphates

- Complex esters

- Dithiophosphates

- Organic friction modifiers

- Phosphates

- Phosphites

- Phosphonates

- Phosphorothionates

- Sulfurized esters

- Sulfurized fatty acids

- Sulfurized olefins

- Triaryl phosphates